Shock-mounted rack cases are an essential infrastructure component of pro rigs for everyone in the band. Whether you’ve got sensitive electronic gear like rack mounted synthesizer sound modules, guitar amp modelers like the Axe-FX, or you need to cradle a rack-mounted tube guitar power amp, shock-rack cases provide the ultimate protection for your gear.

Shock-mounted rack cases are an essential infrastructure component of pro rigs for everyone in the band. Whether you’ve got sensitive electronic gear like rack mounted synthesizer sound modules, guitar amp modelers like the Axe-FX, or you need to cradle a rack-mounted tube guitar power amp, shock-rack cases provide the ultimate protection for your gear.

Brian Kent and his company, Kent Custom Cases, has been building custom cases for everyone from touring pros to indie musicians for decades out of their Buffalo, New York facility. We were initially captivated by Kent Custom’s very reasonable pricing for custom cases—a real savings over some of the older and well-known builders. We would never trust our pricey gear to cheap import cases sold by big box stores or online retailers, and definitely stand by American manufacturing quality when it comes to this type of product.

| Category | Value | Rating |

| Features | 35% | |

| Usability | 35% | |

| Sound | n/a | |

| Documentation & Support | 10% | |

| Price | 20% | |

|

|

||

| OVERALL RATING = 3.7 Stars, which earns it a WIHO Award! 3.6 stars or better: Outstanding, WIHO Award 3 stars or better: Worth considering 2 stars or better: Suited to specific needs 1 star or less: Not recommended |

||

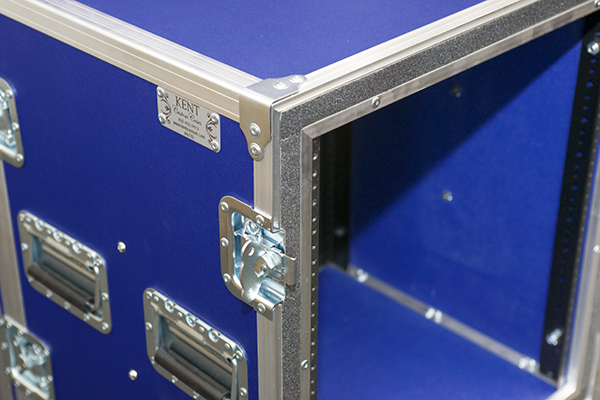

Once we did a little bit of research into Kent Custom’s manufacturing capabilities and techniques, we opted to have them build us a 12U shock rack case for one of our pro keyboard rigs. This case would be equally well suited to one of our guitar effects rigs. Either way, the results were spectacular. We were extremely impressed with Kent Custom’s attention to detail—little things that add up to a superior rack case.

Shock-rack cases are essentially cases within cases, where the interior rack (to which you attach your gear) is suspended via various methods: suspended in foam (the most common method in racks like this), resting on coiled metal cables, or resting on rubber gaskets. The size of the suspension system (foam thickness, diameter of coiled cable, etc.) is related to the level of vibration isolation that the case provides, which will vary based on your intended application, while the thickness of the plywood exterior shell can impact strength/rigidity of the case itself.

We went with ¼” plywood on the exterior, 3/8” on the interior, to help keep weight down overall. The 12U case has rails in front and rear, recessed approximately ½” from the face of the case to protect knobs and switches. With a custom case, you can of course custom spec the depth, and for a case holding keyboard sound modules or guitar rack effects, we found 16” to be a great interior depth that accommodated deep sound modules or shelves and drawers for pedals and other gear. We had a choice of foam density/thickness, and this case was built with one-inch foam as we didn’t need thicker for our solid-state equipment (had we been spec’ing this out for rack-mounted tube amps, we probably would have opted for two- or three-inch foam. But that of course makes the exterior case dimensions larger, heavier, and subsequently pricier.

Brian Kent and Co. consider details that may not even cross your minds: they gave us the option to have the interior rack frame bolted to the exterior case, through the foam. For anyone who ever had an old (or cheap) rack case where the weight of the contents made the rack slowly come out of the foam enclosure, you’ll really appreciate this option.

Custom case reviews at MusicPlayers.com

There are numerous color choices available for custom cases (a plastic laminate over the plywood), and as you can see from the photos, we opted for a deep blue hue. One fantastic and unexpected detail: Kent Cases also applied the blue laminate to the interior of the rack case. It’s a subtle detail that adds a nice air of quality, and avoids splinters when installing your gear, too!

Kent Custom’s details don’t stop there. We loved that they beveled the corners of the caster/base plate. For anyone who has ever connected their shins with the hard, sharp corner of a rack case base, this detail will come as a welcome relief. And as if that’s not enough… it’s what’s inside that counts. There are shock-absorbing, rubber vibration isolators installed between the rack case and the caster base plate!

Kent Custom Cases 12U Shock Rack details

Custom case reviews at MusicPlayers.com

Underneath the base plate, you’ll find four, four-inch, locking casters, as opposed to the common arrangement of just two. You can opt for less, of course, but this is one of their standard details.

The case has a pair of handles on each side, and the case covers are lined with a thin, high-density foam so that there is no interference with rack items like front-mounted wireless antennas or cables/plugs that might extend behind your deepest rack items. The overall weight of our rack case, empty, was around fifty pounds—not too bad!

We are extremely happy with this rack case, and have already put it to good use gigging. The four locking casters make a nice difference (over just two) when transporting the case in an SUV and you don’t want any accidental damage to the interior of your car from case movement/slippage (not really a concern if loading into an equipment van/box truck). Our only complaint is leveled at ourselves: we could really use two more rack spaces!

This specific 12U custom rack case can be ordered for only $475 including shipping. This is an incredibly fantastic price for a USA-made, custom shock rack case! Kent Custom also offer a variety of ready-to-ship configurations through their eBay store at even greater discount, but with such reasonable pricing in the first place for fully custom, American made cases, we recommend simply spec’ing out exactly what you need. All cases include a one-year warranty.

Kent Custom also offers the usual assortment of custom cases for guitar and bass amps, speaker cabinets, wardrobes, and more, so the only real question is, when are you going to order your next custom case?

Contact Information

Kent Custom Cases

www.kentcustom.com